Maintaining and caring for a slitter knife can enhance the quality as well as the output of the slitting process. When selecting a supplier that makes slitter blades, it is crucial to work with an individual who has extensive professional experience to improve the functionality as well as the cut the quality of the slitting knife. Below are the top services provided by a slitter blade supplier.

When shopping around for the best slitter blade manufacturer specializing in top-notch quality knives, you should focus on the services provided. Leading industrial knife suppliers will always provide a variety of services, such as sharpening and rebuilding. These professionals also have a detailed inventory of stock solutions.

1. Sharpening slitter blades

A slitter blade that stays sharp increases the quality of production coupled with its longevity. When sharpened by a professional, the knife takes a new-like condition, ready to make small, precise cuts.

All you need to do is transport that dull slitting blade to a professional sharpener. They will make sure that it is sharpened with significant precision.

For excellent results, establish a proper maintenance routine for your knives.

2. Repair

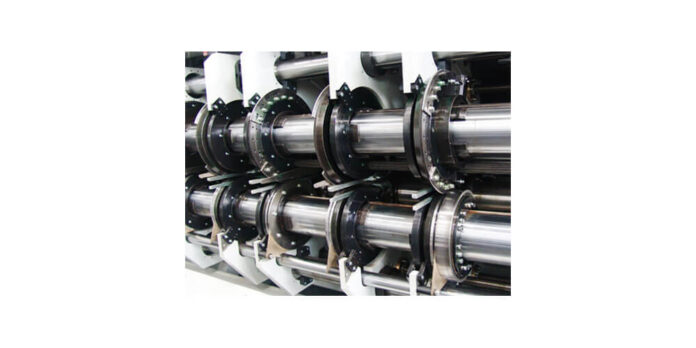

To get quality cuts, while enhancing the life of the slitting blade, a holder needs proper maintenance. Manufacturers of industrial knives can test and inspect and then repair a slitting without hiring a knife repair service provider.

3. Determining if the Knife Holder Needs Repair

To determine if the slitting blade holder needs maintenance, ask a professional knife manufacturer to troubleshoot the slitting machine.

All too often, low quality-cuts can signify that it is time to sharpen the holder. Because faulty slitting blades cause poor-quality cuts, failing to run it at the recommended line speed can contribute to failure. Running the device through a professional will help make sure that the ID of the culprit is secured.

There are a few slitting structures that need the blade to be sharpened together with the aim of maintaining the precision, balance, coupled with efficiency.

Professional slitter knife suppliers should make sure that your blades are sharpened to a precise resilience depending on the slitting machine. This should happen without removing additional material.

4. Inventory

The extensive range of knife sourcing options makes it essential to comprehend the material certification processes.

Top-notch industrial knife suppliers provide blades crafted from trusted materials to meet the set standards of performance and durability.

Multiple industrial cutting applications demand that materials adhere to the set strict tolerances of converting machinery to optimal life and safety.

When the cutting needs a change because of a new material, changes in manufacturing demands, an experienced supplier will discuss your special needs while making recommendations fitting your business objectives.

Final Thoughts

Looking for a reliable supplier of quality slitting blades? Partner with one that provides in-house solutions, such as knife holder maintenance and sharpening. Your decision will decrease reliance on several vendors besides providing simplified access to consultants. An experienced knife supplier with a significant size of stock provides excellent converters who can help find a solution that fits production and other budgetary demands.