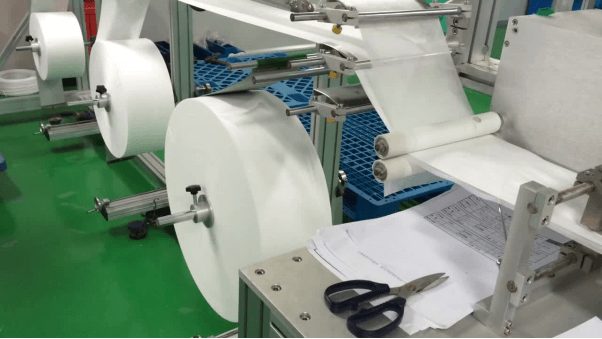

In the modern era, surgical masks are fashioned from non-woven materials obtained from plastic compounds such as polypropylene. A majority of masks have the sole purpose of filtering the air quality, reaching the wearer, and protecting both the wearer and his neighbors in the immediate vicinity from infectious maladies. In addition to this, surgical masks work to maintain a sterile environment in operating theatres. Any contagious microbes in the mouths and noses of the surgeon and his attendant team will not be able to infect the open wounds of a surgery patient. The best face masks are fashioned on high-quality surgical mask machines. Let’s focus on how to maximize surgical mask supply after manufacture.

Versions of surgical masks available in the market

- Level three

These face masks are designed to withstand exposure to corroding chemicals such as fluid, sprays, and aerosol. They can also cope with fluid resistances of up to 160 mercury points.

- Level two

These masks come with a fluid resistance of roughly 120 mercury points. They can only provide minimal defense against spray, fluids, and aerosols.

- Level one

These surgical masks include ear loops. They are the most widely used in surgical operations. The fluid resistance of these masks is roughly 80 mercury points. Ideally, these surgical masks should only be used in situations where the risk of contamination is low.

- Baseline/Minimal protection

These are face masks created solely for short and straightforward activities that do not involve chemicals of any nature.

Quality tests for surgical masks

- The ability to resist catching fire

The number of items in an operating room that can catch fire is high. This test involves measuring how long the mask fabric takes to catch fire and burn.

- Latex particle challenge

In this test, a chemical is sprayed onto the surface of the surgical masks. It measures whether the cover can filter out the components and particles it is meant to filter.

- Bacteria Filtration Efficiency (in Vitro)

In this test, an aerosol containing the staph bacteria is fired at the surgical mask at high pressure. The analysis indicates whether the cover can keep out the correct percentage of bacteria as expected.

- Splash test

In this test, the surgical mask is sprayed with fake blood at high pressure to simulate exposure to blood during operations. It is used to determine how well the material of the cover can resist blood contamination.

- Simulated breathing tests

Here, surgical masks are tested on their ability to maintain shape, and efficient ventilation as the user of the surgical mask breathes in and out.

How to maximize surgical mask supply after manufacture

- You need to understand the inventory and supply chains of surgical face masks

- Take the face mask utilization rate into account when supplying masks made using surgical mask machines.

- Maintain communication with the government and local health partners. This enhances the supply chain of surgical masks.

- Ascertain whether the surgical masks are authorized for reuse. Know which versions of surgical masks can be reused.

- Prioritize face masks for any activity involving sprays and splashes of liquids and chemicals.

Conclusion

Surgical face masks are incredibly valuable in the mitigation of infection and contamination during surgical procedures and also during hazardous activities. An appropriate surgical mask machine can produce high-quality masks that can withstand all the required tests for certification.