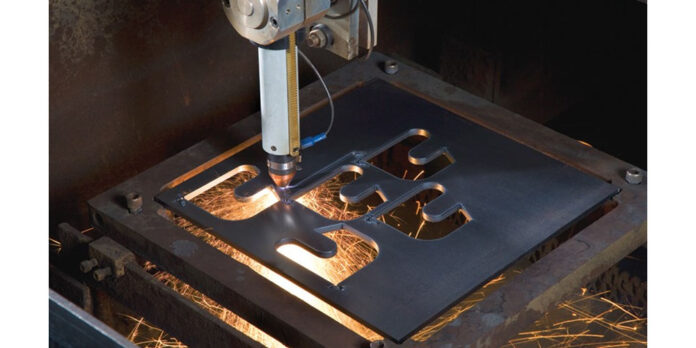

Plasma cutting is an automatic and efficient cutting process commonly used in cutting all types of carbon materials, mild steel materials, stainless steel, and nonferrous precision metals. Globally, China is the leading manufacturer of CNC plasma cutting machines because of its advanced technological innovation and expertise. Some of the leading companies include; Shandong SSR CNC Equipment Co., Ltd, Dezhou Sean Equipment Co., Ltd, and MeisarShangzhou Intelligent Technology Co., Ltd. If you are looking for CNC plasma cutting machines, you can buy here.

Applications of CNC plasma cutting

CNC plasma cutting equipment is commonly used in the woodwork industry, furniture making industry, crafts and gifts, metal cutting, construction industries, automotive restoration and fixation, electrical, advertising, packaging, printing, clothing, and decoration.

The working materials are aluminum, sheets, brass, copper, steel, iron, titanium plates, and galvanized sheets.

When it comes to keeping up with technological innovation founded on customers’ demand, CNC machine usage creates and strengthens a flawless sales network system tailored towards each customer’s needs. Through constant enhancements, companies can build cordial relationships with consumers and agents worldwide.

Features of plasma cutting machines

- The control system uses a U disk exchangewith prescribed procedures for processing files that are easy to operate. If you have to carry out a speed change, do it after stopping with the gear fully engaged.

- Have a high CNC configuration structure, consistent performance, and an automatic capacitance ignition THC or ARC.

- Has an arc success level of 99% and more

- Autonomously examines the system of cooling water to ensure the smooth incision and deformation of materials.

- The entire frame is made of an aluminum alloy element formed at high-temperature.

- The rack is all-welded, solid, simple, and lasting.

- The bed’s workpiece is shaped with a dense steel tube cast into the wall, and it is cooled before welding takes place to remove inner stress.

- The side beam structure is gantry with high-quality aluminum edges, is strong, doesn’t deform, and is lightweight.

- Arrangement of both plasma lights is done at similar times for precise cutting at high accuracy.

- Supports Fastcam softwareinterpreted or scanned by software conversion.

- The machine’s Y-axis has double motors alongside double drivers. The axes round rail moves evenly and accurately.

Some of the measures and precautions to remember when using a CNC plasma cutting machine include;

- Replacement of the cutting tool, quantifying the workpiece, cleaning the pipe head, and lubrication must be done when the machine is not operating.

- Before use, always check if the power line is trustworthy.

- When the machine is in use, prevent any part of the body from making contact with transmission parts.

- Tie cuffs when using the machine

- When freeing the binding wire, be careful to avoid rolling.

Final Thoughts

An efficient and effective plasma cutting process, the CNC machine must meet all the required conditions of HD cutting to enhance production efficiency, decrease operational costs, and completely enhance the cutting process. The machine you land at will depend on what material you want to cut, the thickness of the metal, and the machine’s size.