Heat sinks are very important components that are largely underrated. For those who don’t know what a heat sink is, it’s simply a component that cools a device by transferring the generated heat into other parts of the device or the surrounding air.

In computers, a heat sink is often attached to chips in the CPU to transfer the heat to other parts or the surrounding air. In electronic devices, a large heatsink has cool components such as optoelectronic devices, high semiconductors, or any other component. It produces heat in large quantities because of their fast processing speed.

Now, metals are used to produce heat sinks because of increased conductivity. The two commonly used metals are copper and aluminum. Copper has higher thermal conductivity compared to aluminum, but aluminum is popularly used because it’s not only lightweight but it’s also very affordable.

Companies love using affordable materials to create products so that they can maximize profit. In doing this, most modern metal companies produce heat sinks through aluminum extrusion.

Aluminum Extrusion Explained

The use of the aluminum extrusion process in manufacturing and design has increased significantly in the last decade. But how does it work?

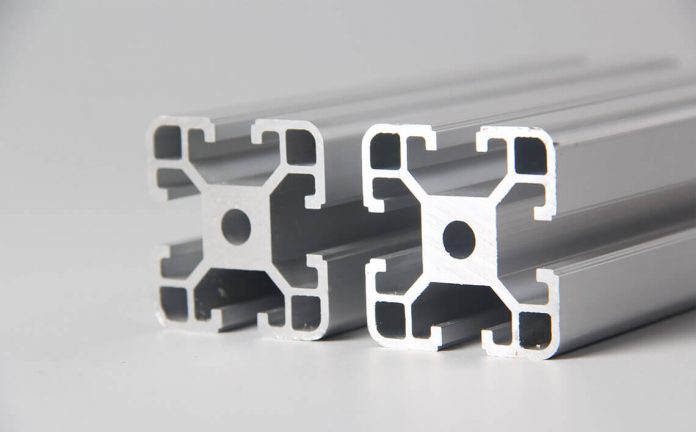

Aluminum extrusion involves forcing an aluminum alloy material through a die with a particular cross-section profile or grid. A ram pushes the aluminum through the die and it comes out on the other end.

As always, the aluminum takes the shape of the die it was pushed through, and as such, it’s rolled out on a run table. At the basic level, this process is super simple to understand. To make it easier, you can liken the aluminum extrusion process to squeezing toothpaste through a tube opening. The opening serves as the extrusion die.

What type of shapes can one extrude?

Three main shapes can be extruded:

- Hollow: this shape contains one or more openings or voids (squares, rectangles)

- Solid: this shape has no openings (angle, beam, rod)

- Semi-hollow: this shape is closed on one end and open at the other

Extrusion can be used for several processes and applications in industries, from electronics, automotive, aerospace, to architectural, energy, and pharmaceutical industries.

The Aluminum Extrusion Process in 10 Easy Steps

- The extrusion die is prepared and transported to the press. Note that the die should be preheated to at least 450 degrees to ensure durability.

- A block of aluminum alloy, known as a billet, is preheated between 400-500 degrees in an oven so that it’s malleable enough for the process but does not melt.

- The billet is moved to the extrusion press. Apply a lubricant to the press before loading the billet onto it. You can also apply a release agent onto it to stop the billet from sticking to the ram.

- The ram drives the billet into the container. The pressure the hydraulic ram applies is over 15,000 tons.

- The extruded material comes out at the other end of the die.

- The extruded material is laid on the runout table and uniformly cooled.

- The extruded material is sheared using a hot saw. Note that the material isn’t completely cooled.

- The sheared extruded material is now moved to a cooling table where it’s cooled to room temperature.

- Twistings in the profile and other misalignments are now corrected.

- The extruded material is moved and cut to the desired length.

Bottom Line

The aluminum extrusion process is crucial to make the best heat sinks possible.