CNC punching enables a metal worker or craftsman to work with sheet metals. It incorporates CNC punch tools and CNC punch presses. CNC refers to computer numerically controlled processes for sheet metal manufacture and design. The CNC punching machine mainly consists of a single head and tool rail design, or can also be composed of a multi-turret system. A CNC punching machine uses applied force to cut and form a target material.

This machine can engrave a metal surface without changing the customer’s initial requirements and design. Secondly, any changes that are needed can be quickly integrated into the device through reprogramming. The advantage of a CNC punching machine is that it offers a lower cost of operation when compared to other techniques such as laser cutting. The tools are also faster when dealing with parts requiring many on-hole processes. One machine can be used to punch and create dynamic forms sequentially. In this write-up, we shall take a look at the factors to consider in using CNC punching to fabricate a sheet of metal.

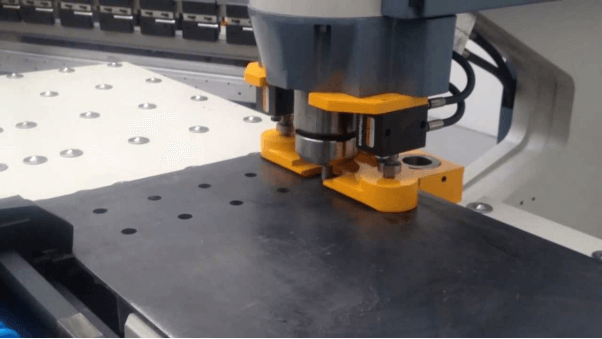

How CNC punching machines work

Many CNC punching machines consist of mini-computers or a smaller micro-computer that is the brain or controller of the device. A sequence of instructions is fed into the computer by typing via a keyboard. Many of the CNC machining programs are versatile and can be re-used for more than one project. This saves the designer/programmer from having to rewrite the instruction sequence over and over. The program directs the machine on how to cut the metal. The most common and prevalent CNC machine types include milling machines, drilling machines, hydraulic punching machine and punchers.

CNC punching works by removing unwanted sections of the metal to leave the sheet with the desired shape. In CNC punching machines, highly experienced operators are not required to direct the sheet metal cutting. The machines are designed to be fully automated: they can finish a job, remove the completed sheet, and pick up the next job entirely on their own.

Uses of CNC Punching machines

These machines are mostly used in mechatronic automation. They’re used in the design and manufacture of air conditioners, kitchen equipment, auto parts, lamps, chassis cabinets, refrigerators, and solar plates.

What to consider when designing CNC punching for sheet metal

- Instead of screws, toy tags cab be applied in the assembly of small, lightweight parts. This mostly comes in handy for light fitting solutions that do not require a lot of strength. The sheet metals used here are so flexible that you can bend them with your fingers.

- When doing CNC punching, the diameters of the holes should not be smaller than the sheet metal’s gauge.

- Machinists can apply cluster tools to minimize the total required time needed for CNC punching of numerous holes repeatedly for several batch jobs. A cluster tool contains many punches on its surface, making it possible for thousands of holes to be punched in a minute.

- It is easy to use plunged forms (by applying tapped holes) to save money in sheet metal fabrication.

Conclusion

CNC punching machines are prime instruments in sheet metal component fabrication. CNC punching can be used to manufacture refrigerators, chassis cabinets, solar plates, and kitchen parts.