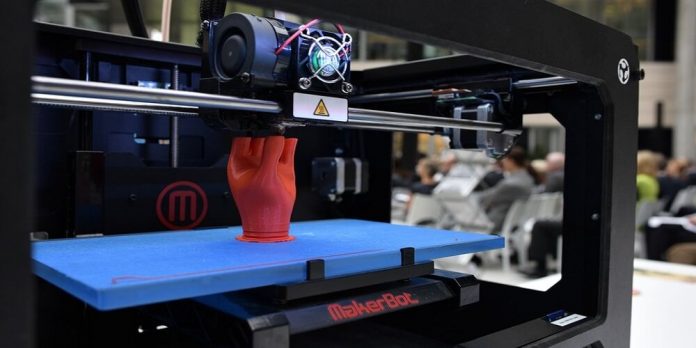

People in the 3D printing world can relate to knowledge builders like this. Getting the right information about 3D printing and 3D slicers is important for better 3D product quality. So, getting a 3D slicer is important.

If you are interested in making 3D prints, you should focus on the product of your print. For best quality, you should check https://www.jgmaker3D.com/ for best quality 3D services.

Nobody wants to have a failed print. The 3D slicer setting is the key to not having a failed print. Fully understanding the 3D slicer and its setting will help you get a successful print.

Knowing the right settings on your 3D slicer, and all the available features have a tremendous effect on the result of your 3D print.

The challenge of the 3D slicer

If you are using the 3D slicer for the first time, chances are you are intimidated by the numerous settings of the software.

If you are a beginner maker, there is no need to feel intimidated by the settings because it gets easier if you keep using and exploring the features of the software.

It is possible to make a mistake. Advanced makers make mistakes sometimes too. And this leads to failed 3D results. So, keep in mind that making mistakes is part of the process of getting better.

A problem that many makers may face is that the design or printing determines the optimal slicer settings. Since there is no setting to fit all in one, it becomes a challenge.

With the numerous settings and features on the 3D slicer, and for those who are either still trying to understand it or those are about to start, here are the 3D slicer need-to-know.

What is the 3D slicer?

The term 3D slicer refers to a 3D printing software that is used to convert the already developed digital 3D models into instructions that the 3D printer can understand.

The instruction is thoroughly analyzed by the 3D printer, then used by the 3D printer to create the object. It sounds easier than it is. But so do most things.

The Gcode is a file sent to your 3D printer where all the information on your digital 3D model that you wish to create is. The 3D slicer can now calculate how much material is needed for the job.

Based on the stings you choose; the 3D slicer will calculate how much is needed to extrude and how long it will take to fully complete the process.

The variety of information on your Gcode sent to our computer is what runs the whole [printing process. Even though a lot depends on the type of settings, nothing can be achieved without the Gcode.

If you wish to get quality results from your 3D printing, you should make effort to get the right software and learn the correct settings.

Quality software and your advanced maker skills will lead to better quality results. The 3D printer Is already built to minimize the waste of materials. So, waste should not be a problem.

Conclusion

You have to remember that there will be a lot of fails. You will have to keep doing it to get better. Continuous use and practice of the 3D slicer software will perfect your 3D printing skills.