Industry

Wholesale Computer Supply: A Cost-Effective Solution for Businesses

Wholesale computer supply is a great decision for busin [ ]

Industry

How to Maintain and Prolong the Life of Your Blow Molding Machine

Hello, my friends! Thanks for joining us on this deep-d [ ]

Industry

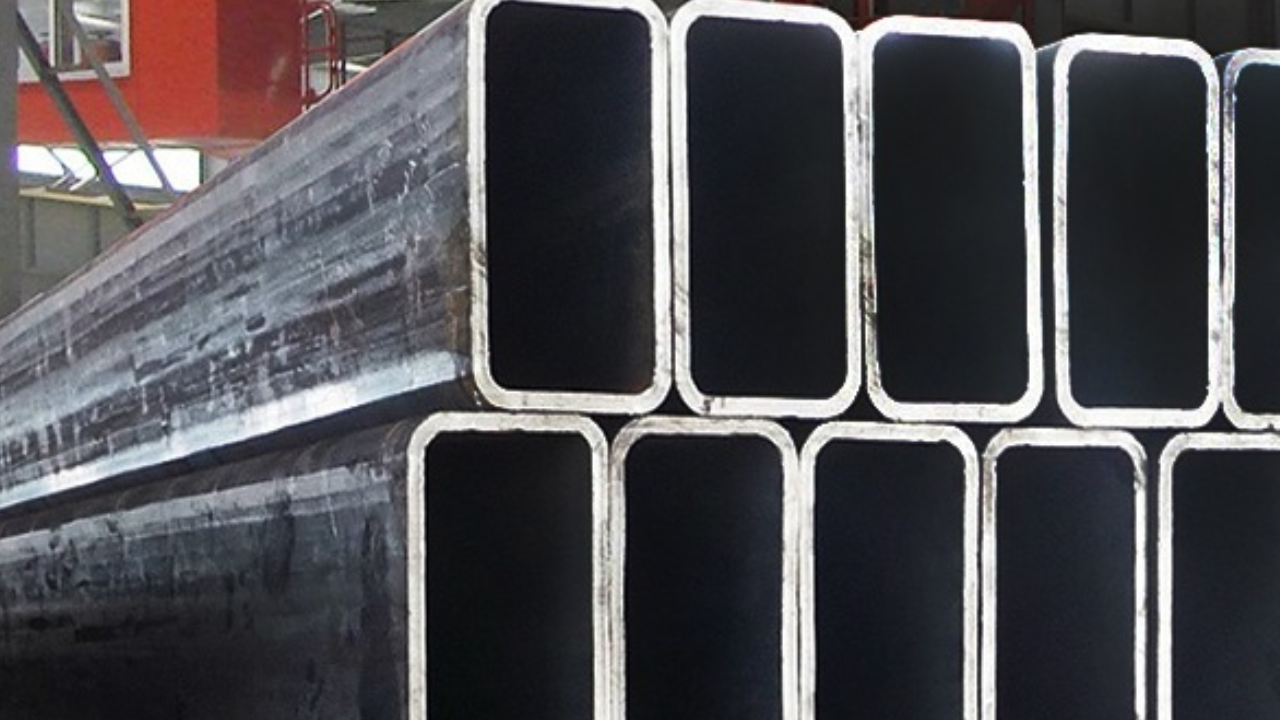

Can ASTM A500 Hollow Section Be Customized To Address Unique Engineering Challenges?

In the realm of modern engineering, the ability to tail [ ]

Industry

The Different Applications of Tricone Bits

Tricone bits are one of the most widely used types of d [ ]

Industry

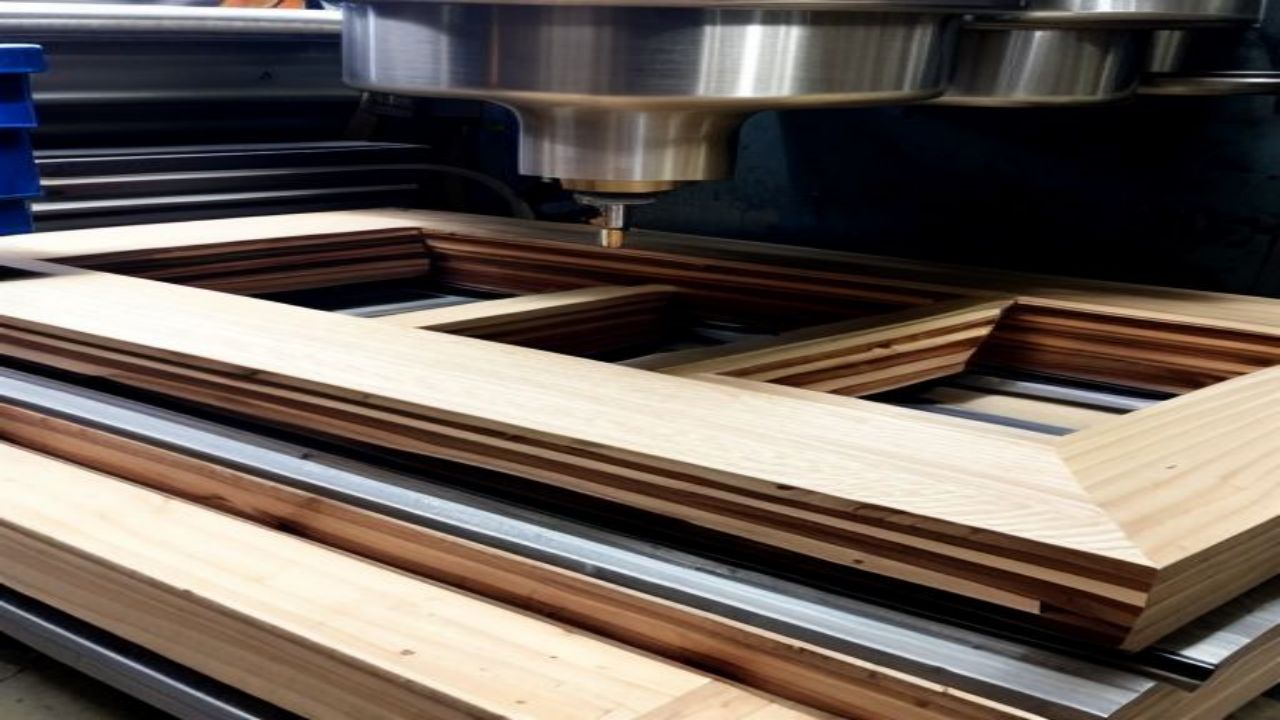

Unveiling the Power of CNC Machining in the New Industrial Revolution

As we step into the new era of intelligent manufacturin [ ]

Industry

Top Benefits of Using Fire Pipes

Are you looking for quality fire pipes for your next pr [ ]

Industry

The Expert Guide to Choosing Appropriate Mining Drilling Bits for Coal Mining Operations

Mining coal is an industry that s profoundly shap [ ]

Industry

Advantages and Applications of Custom Forging

In the world of manufacturing, custom forging has emerg [ ]

Industry

Polyolefin Shrink Film: The Ultimate Packaging Solution by KEEPTOP Packaging

In the dynamic world of packaging, businesses are const [ ]

Industry

PTFE Tube: The Indispensable Component For High-Tech Applications

ePTFE tubing is a remarkable innovation in the technolo [ ]

Industry

How to Choose the Right Thickness for Sandwich Panels?

Choosing the right thickness for sandwich panels is an [ ]