Can ASTM A500 Hollow Section Be Customized To Address Unique Engineering Challenges?

In the realm of modern engineering, the ability to tailor materials to meet specific and unique challenges is paramount. As structures become more intricate and demands grow increasingly complex, the role of customization in addressing engineering obstacles has gained prominence.

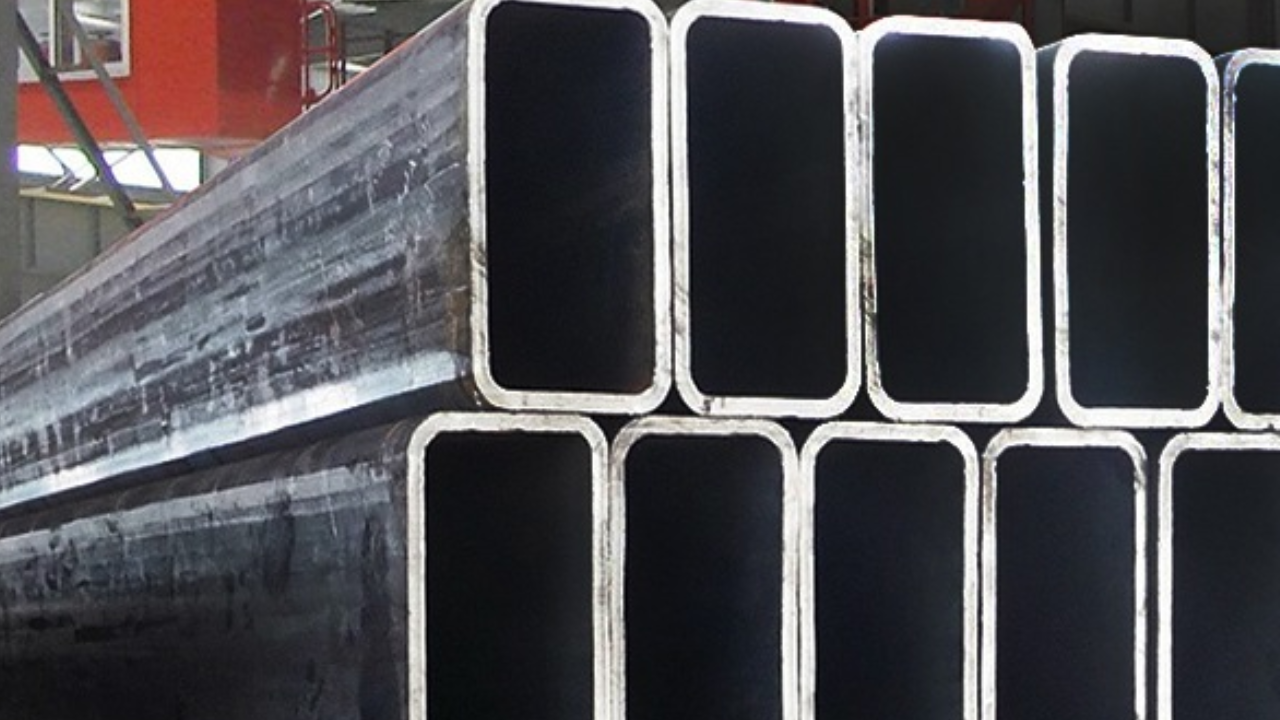

One such versatile material that has garnered attention for its adaptability is the ASTM A500 Hollow Section. With a rich history in construction and engineering, this hollow structural steel has transcended its conventional applications to offer a customizable solution for a myriad of engineering hurdles.

Understanding ASTM A500 Hollow Section

Understanding ASTM A500 Hollow Section is to delve into the realm of versatile structural steel that has left an indelible mark on modern engineering. As a cold-formed welded and seamless carbon steel tubing, ASTM A500 Hollow Section boasts a formidable combination of strength, durability, and adaptability.

This material, meticulously crafted through a process that ensures precision and consistency, has become a cornerstone in construction and architectural projects. Its composition and manufacturing method imbue it with the ability to withstand varying loads and conditions, making it a prime choice for diverse applications.

Customization of ASTM A500 Hollow Section for Unique Engineering Challenges

ASTM A500 Hollow Section serves as a canvas for customization, offering the capability to be tailored to meet intricate dimensions, complex geometries, and specialized strength requirements, making it a versatile solution for unique engineering challenges.

Tailored Dimensions

The innate flexibility of ASTM A500 Hollow Section allows for the customization of dimensions to suit specific project requirements. Whether elongating, shortening, or altering cross-sectional dimensions, this adaptability ensures seamless integration into unconventional designs.

Complex Geometries

With advanced fabrication techniques, ASTM A500 Hollow Section can be transformed into intricate shapes, transcending the boundaries of conventional geometry. This enables engineers and architects to bring avant-garde designs to life, challenging traditional notions of what is achievable.

Enhanced Strength

In scenarios demanding heightened load-bearing capacity, ASTM A500 Hollow Section can undergo customization to enhance its strength attributes. Through controlled modifications, it can be fortified to endure the rigors of heavy-duty applications.

Corrosion Resistance

Custom coatings and treatments can be applied to ASTM A500 Hollow Section, rendering it corrosion-resistant even in aggressive environments. This level of customization ensures longevity and performance in diverse conditions.

Temperature Extremes

From scorching deserts to freezing tundra’s, customization allows ASTM A500 Hollow Section to withstand extreme temperatures. Tailoring the material’s composition ensures structural integrity and functionality, regardless of the climate.

Seismic Resilience

In seismic-prone regions, customization can bolster ASTM A500 Hollow Section’s ability to absorb and dissipate seismic forces. This adaptability lends itself to constructing structures that can endure unexpected ground motions.

Aesthetic Adaptations

Customization extends beyond functionality to encompass aesthetics. The material can be tailored to meet specific visual preferences, seamlessly integrating engineering prowess with design sensibilities.

Real-world Applications of Customized ASTM A500 Hollow Section

In real-world applications, customized ASTM A500 Hollow Section breathes life into awe-inspiring architectural designs, enabling the creation of curved facades and distinctive structures that redefine urban landscapes.

Curved Architectural Designs

Customized ASTM A500 Hollow Section breathes life into curved architectural designs, allowing for the creation of striking facades and distinctive structures that redefine urban landscapes.

Specialized Industrial Equipment

In industrial sectors, customization of ASTM A500 Hollow Section proves invaluable. From customized machinery components to specialized equipment frames, it adapts to the unique demands of manufacturing processes.

Unique Bridge Construction

Bridges, the lifelines of infrastructure, benefit from customized ASTM A500 Hollow Section. Tailoring the material to intricate bridge designs ensures both structural integrity and visual harmony.

Resilient Seismic Structures

In regions prone to seismic activity, customization of ASTM A500 Hollow Section contributes to resilient building structures. It forms the backbone of seismic retrofitting projects, fortifying existing structures against unforeseen tremors.

Conclusion

ASTM A500 Hollow Section offers a canvas upon which engineering innovation thrives. As the realm of construction and infrastructure continues to evolve, ASTM A500 Hollow Section stands as a testament to the possibilities that arise when engineering meets customization, reshaping the landscape of modern engineering solutions.