As we step into the new era of intelligent manufacturing, there’s one technology that takes center stage – Numerical Control (CNC) Machining. Its significance in reshaping the industrial landscape cannot be overstated. In this article, we’ll delve into the core of CNC machining companyand explore how it aligns with the principles of the new industrial revolution – Industry 4.0.

CNC Machining at the Heart of Industry 4.0

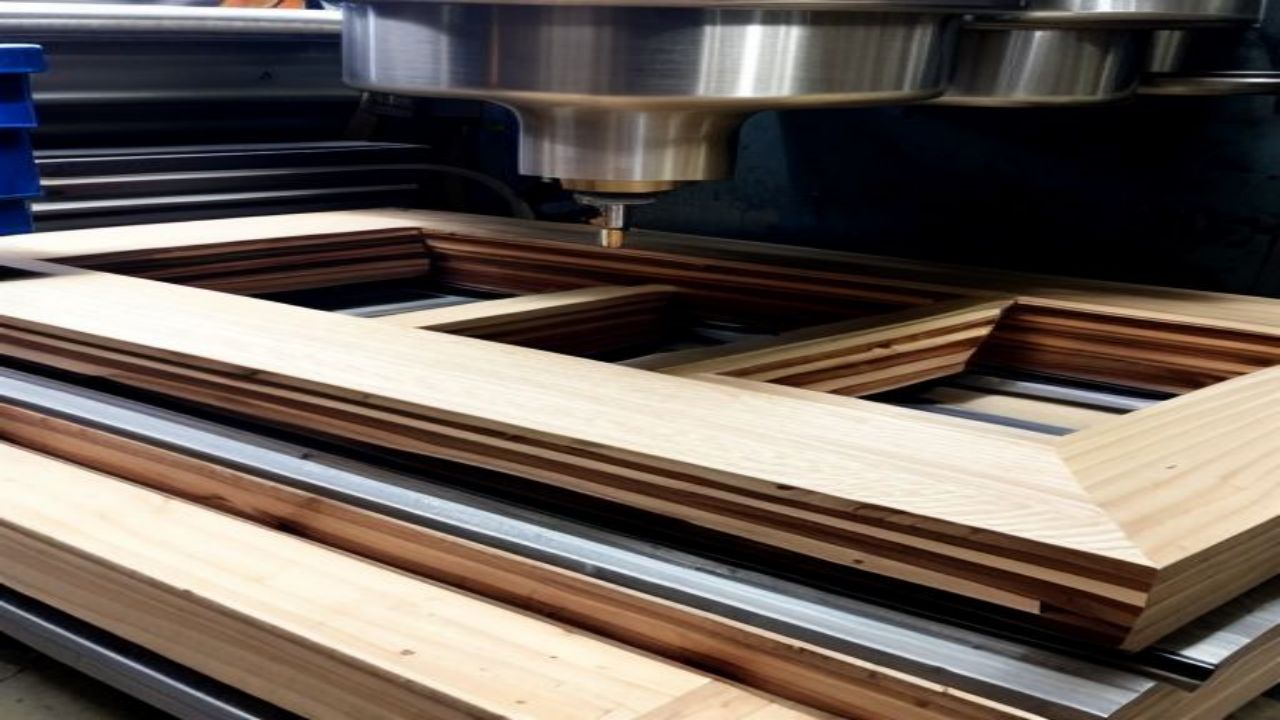

Picture a world where manufacturing processes are no longer bound by manual limitations, but driven by precise digital instructions. That’s exactly what CNC machining brings to the table. By integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) software, manufacturers can create intricate components with unparalleled accuracy and consistency.

The Fusion of Intelligence and Manufacturing

In the grand scheme of Industry 4.0, intelligent manufacturing is the guiding light. It’s a seamless marriage of cutting-edge technology and traditional industrial processes. And guess who’s the star of the show? Yes, CNC machining once again. With its ability to optimize production workflows, minimize waste, and produce high-quality parts on a large scale, CNC machining epitomizes intelligent manufacturing.

Riding the Waves of IoT and AI

But the excitement doesn’t stop there. As the Internet of Things (IoT) and Artificial Intelligence (AI) gain momentum, CNC machining embraces these technologies with open arms. IoT sensors integrated into CNC machines collect real-time data on performance, efficiency, and maintenance needs. Enter AI, the master analyst, who processes this data, identifies patterns, and suggests optimizations. The result? A production process that’s not only precise but also proactive in preventing disruptions.

The Human Factor: Adapting the Workforce

Now, here comes the big question on everyone’s minds: Will intelligent manufacturing steal jobs from hardworking people? The answer isn’t as bleak as some might think. Yes, automation will replace some tasks, but it also opens up new opportunities. Skilled operators who can navigate the complexities of intelligent CNC systems will be in high demand. The key is upskilling and reskilling the workforce to embrace these technological advancements.

Navigating the Challenges

Of course, every revolution faces its challenges. As CNC machining intertwines with IoT and AI, concerns over data privacy and cybersecurity become paramount. Establishing robust regulations and standards will be critical in building trust and ensuring secure implementations. The journey towards intelligent manufacturing may not be without its bumps, but facing these challenges head-on will pave the way for long-term success.

Conclusion

CNC machining isn’t just about cutting metal; it’s a symbol of innovation, progress, and adaptability. In the new industrial revolution, it sits on the throne of intelligent manufacturing, powered by IoT and AI. The fusion of human ingenuity and technological prowess propels us forward, creating a world where precision, efficiency, and intelligence converge. As we continue to explore the depths of CNC machining and its role in Industry 4.0, let’s embrace the future with open arms. Together, we’ll unlock the true potential of CNC machining and forge a path towards a smarter and more prosperous industrial landscape.