CNC milling is a computer-controlled milling process. CNC milling cutting tools are operated and controlled by G-code or computer-numerically controlled. CNC milling is in many ways and forms similar to milling and drilling. This is because the process starts with a large workpiece cut and drilled to achieve the desired shape. The cutting tools move in different directions on varying axes according to the G-code instructions. China hosts some of the best CNC milling companies and factories in the world. Click here (https://www.china-machining.com/services/cnc-machining/cnc-milling/) for information on one of these companies. This post covers the CNC milling process.

The process of CNC milling

Note that CNC milling is a kind of CNC machining. This implies that it doesn’t work the same way as CNC machining, even though it utilizes Computer Numerical Control. The CNC milling process isn’t so entirely different from conventional drilling or cutting. Like other CNC machining processes, CNC machining also uses the same basic principles.

1. Creating the CAD model

As is the case with other CNC machining processes, the first part of CNC milling is the creation of the CAD model. This is done using CAD software and is also known as designing the virtual presentation. It can also be done using G-code.

2. Programming the CNC milling machine

After the model is created, the next step is programming the machines. This is where the G-code is translated into a language that the device can understand, then fed into the machine. The programming can also be done manually.

3. Cutting

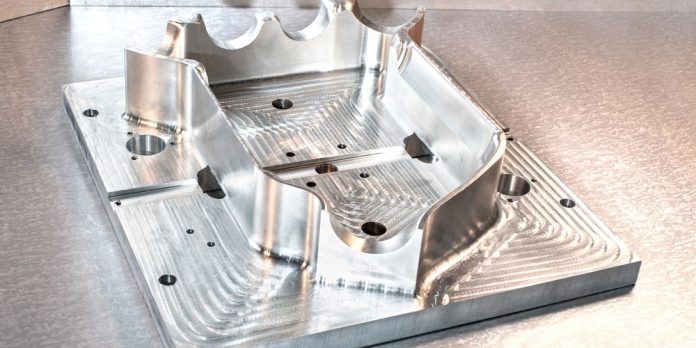

CNC milling machines utilize cylindrical-shaped cutting instruments. These stools turn in different ways on various axes when performing the cutting functions. These cutters move in varying directions along the different axes because of the trend-setting innovation and the machines’ inclination.

These machines additionally can make a wide scope of shapes, spaces, openings, and different impressions, contingent upon what you need to make. Note, with CNC milling machines, it is possible to have your materials or workpiece into explicit bearings within the milling apparatus.

Standard milling or drilling techniques could just accomplish an individual hub movement at a time. This implies that CNC milling machines are better with regard to design capabilities.

What separates CNC milling from other forms of milling?

One of the main separating factors between these two operations is the design capabilities and the application of computer numerical control.

Other than the general creation capacities, another huge distinction between conventional milling machines and CNC machines accept their directions through G-codes. The guidelines are taken care of into the gadgets through the CNC control board and converted into the CNC control, which turns out to be the machines’ controller or brain.

Conclusion

In simpler terms, the process of CNC milling can get explained in the following ways;

- Designing of the CAD model of G-code using CAD software

- Converting the model into a CNC program that the milling machines can understand

- Setting up the CNC milling machine and feeding the instruction through automatic or manual programming. The administrator does this.

- Conducting the milling or cutting process.