In Chemistry, the word filtration refers to a process through which solid materials are separated from liquids in a mixture. The process can either be chemical, physical, and at times biological, and it can only occur when the solids have not dissolved in the liquid. Also, the process involves the use of a filtration medium. A filtration medium is an object that aids in the separation of two objects, usually with a structure that allows the fluids to pass through and does not let the solids through. In the process, the fluids are referred to as the filtrates, while the solids are known as the oversize. In this write-up, we discuss some filtration media types.

Categories of filtration media

There are two main categories of filtration media in the market. They are;

- Surface filters- surface filters are those that are used to trap solid particles. These filters can either be used with or without a filter paper. In simpler terms, they can be referred to as solid sieves. Examples of these filters include cross-floe filters.

- Depth filters- depth filters are those that work by retaining solid particles as they pass. This type of filter allows you to collect the intact solid particles. In simpler terms, these are ones that use filter papers for added efficiency. An example of a filter in this category is a sand filter.

Most common examples

- Metal Woven Mesh

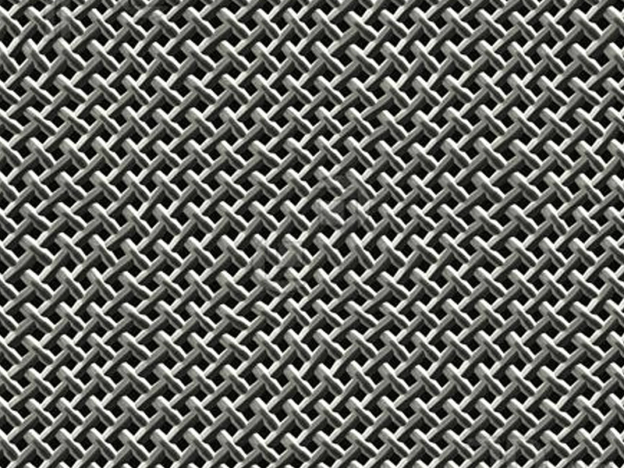

Metal is one of the best materials for the manufacture of a variety of materials. The reason for the popularity of metal is the fact that it is one of the most durable kids of materials in the market. However, as a filtration media, metal can be quite hard to maneuver because of its hard nature. However, manufacturers have been able to move past this challenge by creating woven mesh out of metal. Metal woven mesh filters are coated with rust-resistant material that helps with durability. They are available in a variety of mesh sizes, depending on the role.

- Sintered Porous Plastic

This one of the most popular types of filtration media in the market. This type of material can be used for a variety of functions and in different industries. They can either be manufactured from thermoplastic polymers, the likes of polypropylene and polyethylene. The filters made from these materials also have different sizes of pores depending on their function and the area they are to be used. Additionally, sintered porous plastic is resistant to several elements, including heat and chemicals of a variety of kinds. It is also one of the most durable kinds of materials for filters in the market.

- Sintered Wire Mesh Composite

This type of filter is manufactured from stainless steel wire material. They are available in a variety of sizes, shapes, and designs depending on the manufacturer and the purpose of the product. The materials are at times combined with other elements like perforated plates, which allow for added support.

Conclusion

The term sintering refers to a process of compacting a material and forming a solid mass by using heat or pressure. It is performed in such a way that the solid mass does not reach a point where it melts.