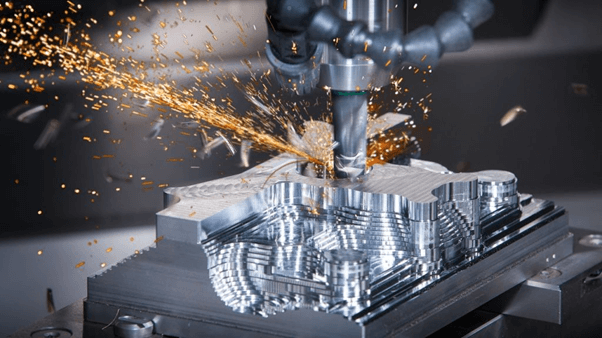

As we discussed in the earlier chapters of our series, CNC machining refers to a careful manufacturing process where there is pre-programmed computer software that dictates every movement of different factory tools as well as machinery. Let us look at CNC machining services and prototype specialists.

Usually, the process may be utilized in

controlling different complex machinery, including grinders as well as and

mills. In the long run, with CNC machining and the 3-dimensional cutting projects

may be accomplished in one set of different prompts.

CNC is the abbreviation for computer

numerical control. It is also prominent in the industry of enhancing different products

to look good in all ways. There are; however, several limitations appended to

the CNC processes.

To you, as the onlooker, this system can

resemble a significant regular set of different computer components. However,

the software programs, as well as consoles employed in the CNC machining, play

the role of distinguishing it from various elements of computation.

Fundamental

Details Of CNC Machining

To comprehend the basics of a CNC

machining, you need to know how it works. To begin with, the CNC system is first

activated. After that, the required cuts will be programmed into the software.

That software is going to be dictated into a corresponding tool.

It will also be dictated into the

machinery, which can carry out different dimensional tasks. The coding

generator in the system will, most of the time, assume that the mechanisms are

flawless. This is regardless of the possibilities of the occurrence of

different errors, which should definitely be more significant when a CNC

machining is directed to cut into more than a single direction at the same

time.

Typically, the placement of your tool in

the numerical control system will be outlined using different series of inputs.

These elements are known to be part of the primary program for various CNC machines, which are

often fed into the memory of a computer. The code in itself is usually written

as well as edited using different programmers. For that reason, CNC systems

provide more than just the expansive computational capacity.

The best part about it all is that CNC

systems are not static. Therefore, newer prompts can easily be included in the

different pre-existing programs via a revised code.

Benefits

Of CNC Machining

The industry in charge of manufacturing

products highly relies on CNC machining. The operational elements of these

sectors include engineer-operated elements such as routers, vertical millers,

as well as shaping different machines. In the end, the advantages appended to

CNC machining imply that the operator-needed equipment has been replaced

entirely. Manufacturers of different types of products across various

industries will often choose the pros of CNC machining when it comes to the

fabrication as well as manufacturing applications of different products. This

is sole because CNC machining offers efficient as well as expedient production

capacities, which are perfect for the creation of large quantities of products.

Take-Home

In closing, CNC machining can be used in producing a variety

of metal as well as different plastic elements that may become a significant

part of the business. Several industries demand accurate yet sophisticated

cuts. Some of the industries include:

- Production

- Military

- Hospitality

- Dental

- Metalwork

- Electronics