A gearbox refers to a mechanical device used in increasing the total output of a motor. It can also be used to change the motor’s speed. So what are small geared motors?

The shaft of the motor is often attached to the end of the device via an internal configuration of different gears of the gearbox, thereby providing an output torque that is determined by the ratio of the gear. So what are the best small gearboxes, and what are their physical properties?

Background Look on Physical Properties

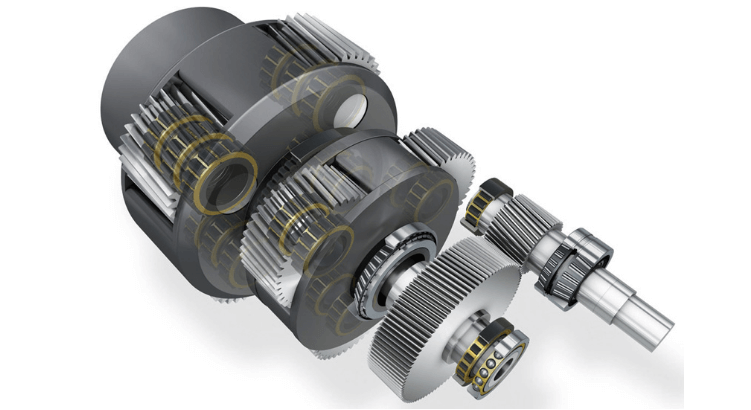

Gearboxes have different physical properties. The physical components of these devices vary depending on their manufacturers. Most gearboxes are designed and constructed from various steel materials, including aluminum and brass.

Unlike other types of gearboxes, a spur gearbox may be made using plastic, such as nylon. Apart from the raw materials that shall be used, the actual orientation of the teeth of the gear plays an important role in the general efficiency and total speed of the gearbox system. Gearboxes with straight teeth can be used in applications that require low speed.

On the other hand, helical gearboxes, being noisy, will be utilized in applications that require high speed. The gearboxes mentioned herein seem to be quieter when it comes to operation as compared to the straight gear teeth boxes that can offer to improve the overall efficiency of what you are dealing in.

The Types of Small Gear Boxes

There are several types of gearboxes manufactured in the world. They also come with different features that create these differences. One primary difference they all have is the fact that they register various performances and characteristics. Selecting from the existing types on the market is dependent on their application.

Usually, gearboxes come in multiple sizes, efficiencies, as well as backlash characteristics. All these are design factors that shall impact the general performance of the gearbox. As such, there are these types of gearboxes listed below:

Bevel Gears

This gearbox comes in two main types. There is the straight and then the spiral teeth one. All too often, the straight bevel gears come with tapered teeth. They are also used in applications that demand high-performance and high speed. Bevel gears are made from aluminum and cast iron, among others. But this highly varies between manufacturers as well. Gears manufactured from steel can be pretty much noisy, especially when you come into contact with them.

Helical Gearbox

Helical gears are often cut into different angles. This process allows for continuous contact between every helical gear teeth. The innovation type offers for a relatively smooth yet quiet operation. Gearboxes that make use of helical gears are known to be applicable in inefficient operations.

Final Thoughts-How to Control a Gearbox

Usually, the output of your motor, that is, the brushless motor, is often used as your input in the gearbox industry. It controls the total speed with which your gearbox rotates. The total configuration should illustrate how the driver controlling the motor that is connected to the gearbox rotates.