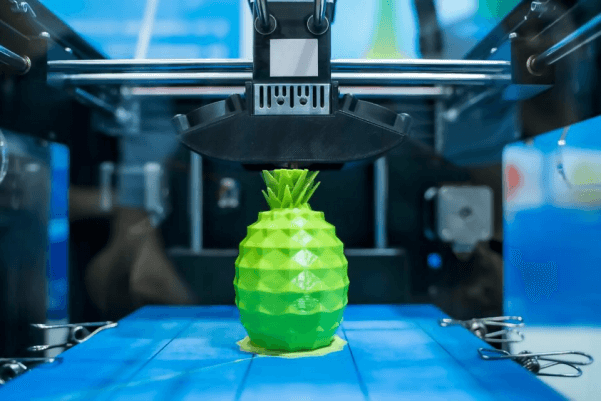

3D printing is also known as additive manufacturing and refers to the process through which 3D items are made. This whole process starts with a 3D model in a digital file. This innovation has taken the world by storm and is changing the field of manufacturing opening doors to new production possibilities.

The most amazing feature is the Printing Resume Function which allows users to stop/pause a printing job and resume afterward. In ideal situations, we start a printer and only turn it off after we’re done the printing. However, things will not always be smooth and at some point, you will need to stop the job before completion. This interruption doesn’t spell doom. The printing resume function allows you to restart the printer and pick up from exactly where you had left it off.

How 3D Printing Works

In additive manufacturing, the object is created by laying down several layers of materials until the final object is created. Each of the successive layers can be viewed as thin horizontal cross-sections of the whole object.

Through 3D printing, you can create very complicated shapes. Once you have a 3D model ready, prepare the digital file for your 3D printer through a process known as slicing. The process involves the division of the model into thin horizontal layers. After the file is ready, you then feed it into the 3D printer where it’s then printed layer by layer.

The biggest advantage of 3D printing is that you use fewer materials as compared to traditional manufacturing methods.

Types of 3D Printers

There are different types of 3D printers and it’s important that you take your time to investigate which is the right one for you to use. One main difference arises in the type of printable material i.e. there’s the resin-based 3D printer and the filament-based 3D printer.

The other main difference lies in the product development process. Although all the 3D printing technologies used are additive, they differ in the way in which the build-up of the layers to create the final object. While some machines use melting materials to produce the layers, other machines work by curing a photo-reactive resin using a UV laser layer by layer.

Applications of 3D Printers

3D printing has been adopted very well in almost all industries that you can think of. As the technology keeps changing, we expect that it’ll change almost every major industry and this will impact in a great way, how we live. The main reason why 3D printing has been embraced is that it’s fast and relatively cheap since you don’t need any additional expensive tools.

The main applications of 3D printing are:

- Automotive

Car manufacturing companies use the technology to print spare parts and tools. These 3D printed parts may be used to restore old cars that aren’t functional anymore.

- Healthcare

Although 3D printing technology started out as experimental for most of its application in healthcare and medicine, today it’s widely used to create implants, prosthetics, dental crowns, and dentures, hearing aids among other uses.

- Aviation and Aerospace

3D printing is used in the aviation and aerospace industry in so many unimaginable ways. The creations include (but are not limited to) rocket engines and fuel nozzles.

- Education

3D printing technology has enabled both educators and their students to bring their ideas to life in a quick and affordable way.

- Jewelry

Jewelry can also be created through 3D printing in two main ways. The first one involves printing the pieces directly using Metal Powder Bed Fusion and the second one involves printing a tool that will be used to create the pieces through casting.

- Construction

The future of the building and construction industry lies in 3D printing. It’s possible to print doors, windows, walls, floors, and even complete houses.